Fax:86-510-86361211

Add:Changshou, Jiangyin City, Jiangsu Province, China

Postcode:214424

Product Details

Scope of Application

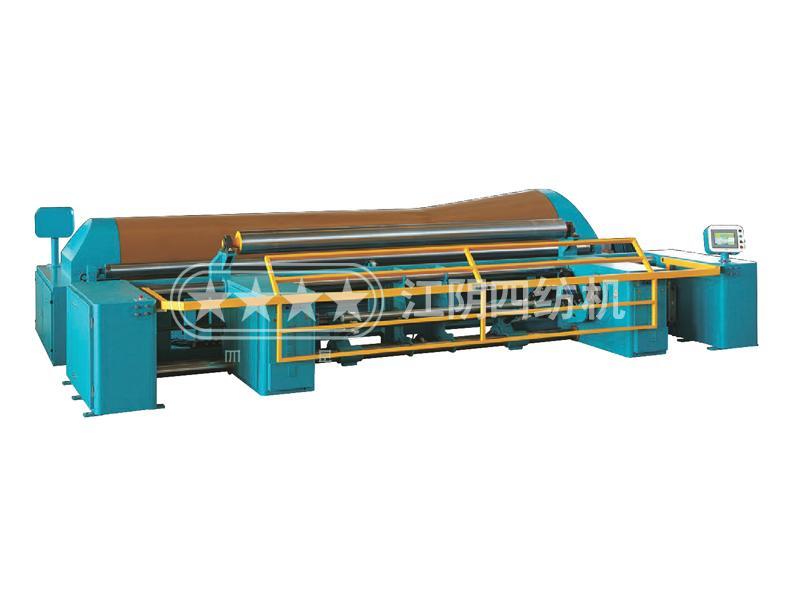

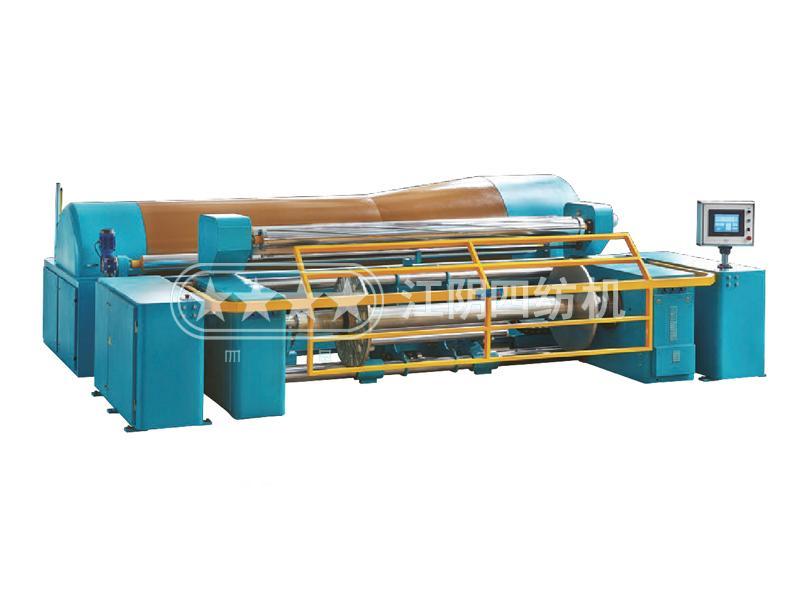

This machine is suitable for batch warping of various short fibers. It features high warping efficiency and uniform, smooth warp beam density, making it an ideal preparatory equipment for various sizing and dyeing equipment.

Main Technical Features

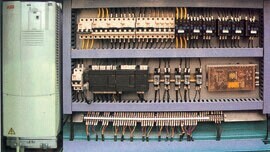

1. Electrical Control System

It adopts Siemens industrial control system from Germany, ABB drive system from Switzerland, sensors from Germany and Japan, pneumatic components and touch-type human-machine interface. The technology is advanced, and the performance is stable and reliable.

2. Length Measuring System

It applies multi-channel sensor line measurement technology and automatic error correction technology, using advanced software algorithms. The length measurement error is controlled within 0.25%, improving output and reducing warping consumption and costs.

3. Transmission Scheme

It adopts AC frequency conversion technology for direct drive of the warp beam. With full digital control and constant linear speed winding (fully digital speed control, measurement, and setting), it achieves high warping efficiency and low energy consumption.

4. Warp Beam Adjustment

It offers both mechanical and automatic adjustments for the relative position of the warp beam flange and pressure roller, solving the problem of warping pressure deviation from the warp beam center caused by warp beam issues.

5. Warp Beam Braking

It uses a high-efficiency clamping brake, applying air power and air-hydraulic boosting technology. Braking is sensitive, rapid, with high braking torque and short braking distance.

6. Warp Beam Pressure

It adopts indirect pressure technology, eliminating pressure fluctuation problems. The warp beam is round and even, with uniform winding density. The pressure roller pressure is adjustable from 150N to 6000N. The pressure roller is controlled by an independent pneumatic mechanism and automatically retracts during braking, eliminating friction between the pressure roller and the warp yarn, ensuring warping quality.

7. Beam Mounting Mechanism

It uses a mechanical transmission mechanism and a bevel gear type warp beam connector. Clamping and disengagement operations are stable and reliable. It also has a pneumatic warp beam lifting mechanism, and different specifications of warp beams can be used on one machine, making it convenient and practical.

8. Reed Mechanism

The precise telescopic reed has functions of lateral alignment and warp density adjustment. There is also a set of gap blowing mechanism to ensure the cleanliness of the reed teeth. The fully sealed telescopic reed device also solves the interference of dust and flying fluff, reducing breakage rate.

9. Baffle Plate

The baffle plate can automatically adjust its position according to the operating status of the equipment, isolating the airflow and most of the flying fluff from affecting the machine, further reducing the breakage rate and improving warping efficiency.

10. Human-Machine Dialogue

The imported large-screen Chinese touch screen intuitively displays various warping data and allows convenient input of process parameters. It also provides Chinese fault diagnosis results, facilitating user maintenance.

11. Safety

It is equipped with a safety protection mechanism. The yellow safety bar also has a

stopping function.

12. Bobbin Rack

Various specifications of bobbin racks and tensioners can be selected by the user.

Main Technical Parameters

|

1. Width: 1600-1800mm (various specifications can be customized as needed) |

Integrated Pneumatic System |

|

Main Drive and Opening/Closing Device |

Siemens PLC Industrial Control System |

Keywords:

GA269C High-speed Sectional Warping Machine

Previous Page

Previous Page

More Products

Online Message

We can recommend suitable products for you according to your needs. Please fill in the following form, and we will contact you in time!

Inquire Now

Inquire Now