Fax:86-510-86361211

Add:Changshou, Jiangyin City, Jiangsu Province, China

Postcode:214424

Product Details

Scope of Application

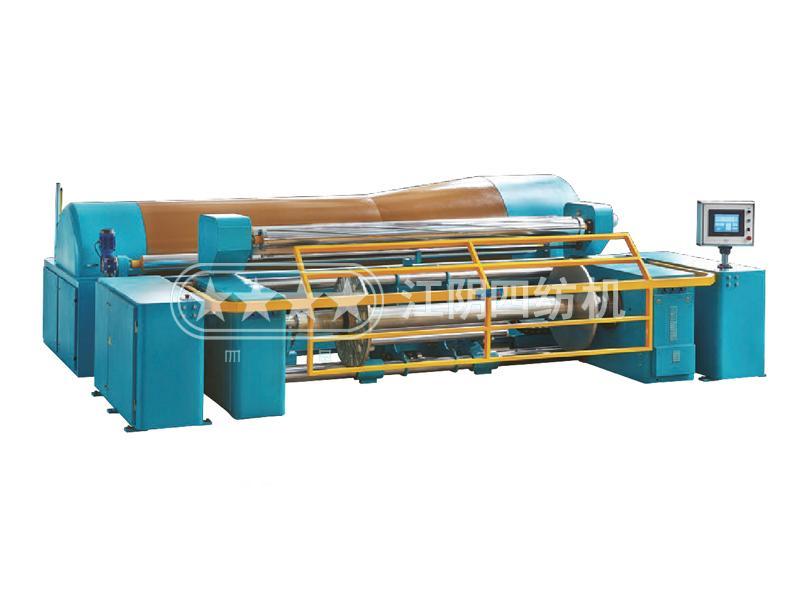

Applicable to warping and beaming for special industrial textiles using various composite materials in industries such as geotextile, construction, agriculture, sports, protection, apparel, packaging, transportation, aerospace, etc. It can serve as a pre-weaving preparation equipment for shuttleless looms like rapier and air-jet looms, and is the preferred equipment for special fabric weaving factories to develop various special fabrics.

Main Technical Features

● Warping and beaming drive controlled by AC frequency conversion, ensuring constant linear speed, constant tension, and high-speed operation.

● A specialized machine, electrical, hydraulic, and pneumatic integrated oil pressure device generates oil pressure to drive the caliper brake, completing warping brake control. The proportional valve controls the heavy external steel belt damping method, achieving automatic control of high tension during beaming.

● The warping servo drive adopts a dual servo motor ball screw structure, offering fast response and high precision. Both strip positioning and starting point positioning are automatically completed with a single button press.

● AC digital servo and ball screw driven warping table for forward and backward movement control, achieving equidistant backward movement of the warping table during the warping process.

● The warping table is equipped with a laser measurement sensor to repeatedly measure the thickness of the warped yarn layer, achieving automatic measurement of warping displacement parameters. The press roller ensures a flatter yarn surface.

● Two sets of specially treated tension rollers are precisely controlled by high-power servo motors, linked with the pressure sensor on the warping table to achieve precise control of high tension throughout the warping process.

● Thick steel large drum, with baked paint surface treatment, excellent adhesion and corrosion resistance, and high-precision dynamic balance calibration.

● Adopts communication technology, integrated mechanical, electrical, pneumatic, and hydraulic design. Configured with multiple sets of PLC, multiple AC digital servo frequency converters, and two touchscreens, resulting in an advanced, reliable, and highly automated system.

● The main warping machine moves on the ground rail, while the dividing frame, tension frame, and creel are fixed, ensuring that the strip remains centered relative to the dividing frame and creel, making the selvedge yarn tension more uniform.

● Dual frequency conversion motors and high-precision helical gear reducers ensure greater tension during beaming and smoother transmission.

● Pneumatically controlled safety railing device ensures safer and more reliable operation during beaming.

● Reinforced creel, with spindle pitch and number of spindles selectable according to user requirements, and equipped with various types of bobbins and anti-ballooning devices for selection.

● Various types of high-precision high-tension tensioners and reinforced warp stop motion devices are available for user selection.

● The warping table is equipped with an electrostatic elimination device, and the beaming machine is equipped with oiling and pressurizing devices for user selection.

Main Technical Parameters

Keywords:

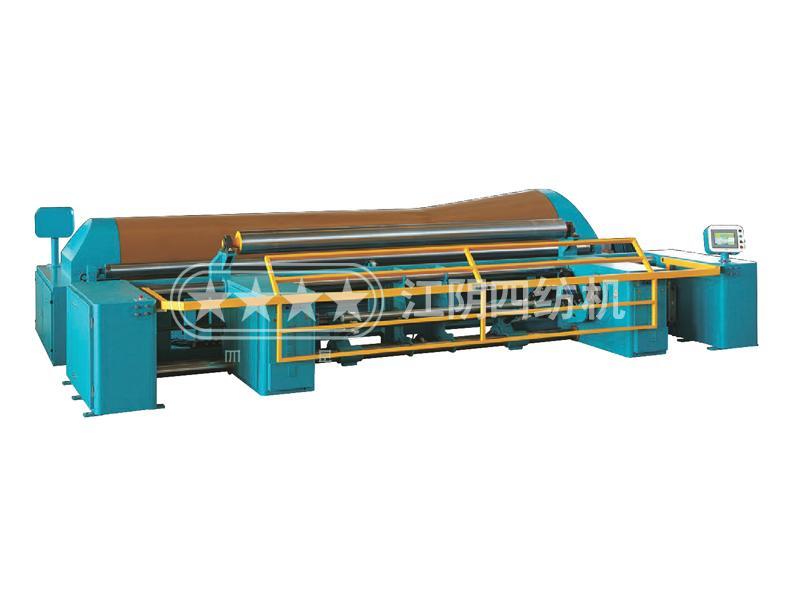

GA163H (heavy duty) type slitting and warping machine

Previous Page

Previous Page

More Products

Online Message

We can recommend suitable products for you according to your needs. Please fill in the following form, and we will contact you in time!

Inquire Now

Inquire Now