Fax:86-510-86361211

Add:Changshou, Jiangyin City, Jiangsu Province, China

Postcode:214424

Product Details

Scope of Application

Suitable for sizing and warping various fabrics, including fine worsted fabrics, chemical fiber filament fabrics, color-woven fabrics, silk fabrics, and special industrial textiles. It can be used as pre-weaving preparation equipment for various loom types such as rapier looms, projectile looms, water-jet looms, and air-jet looms. It is the preferred equipment for weaving mills developing various high-grade and special fabrics.

Main Technical Features

1. Warping winding is controlled by a high-power servo motor, ensuring constant linear speed and high-speed operation.

2. The tensioning unit, composed of a yarn guide roller and a pressure roller, is precisely controlled by a high-power servo motor, achieving precise tension control throughout the warping process (including during stops), while ensuring the same length and tension between yarns and between warps.

3. The servo motor-controlled yarn storage system works with the tensioning unit to ensure strict tension control even when handling broken ends by reversing the winding roller, minimizing warp breaks. There are spare bobbins above the warping creel for handling broken ends.

4. No need to set displacement or warp width, making operation simpler.

5. Two sets of high-power servo motors work with high-precision helical gear reducers for active winding and unwinding, ensuring constant closed-loop tension during rewinding and smooth transmission.

6. Warp transmission is driven by a dual servo motor-controlled ball screw structure, offering fast response, high precision, and automatic completion of warp positioning and starting point positioning via simple button presses. Fine-tuning of centering is possible for different warp widths without affecting warp control.

7. The warping creel moves back and forth via servo motor control and ball screw transmission, allowing the creel to retreat at an equal distance, preventing warp spreading. It is equipped with a pressure roller, a laser measurement sensor, and a pressure sensor.

8. A specialized hydraulic device generates oil pressure to actuate the clamp-type brake, completing the warping braking control.

9. Using communication technology, the machine features an integrated design of mechanics, electricity, pneumatics, and hydraulics. The system is equipped with a high-performance PLC, seven sets of AC digital servo systems, an industrial computer, and a touch screen, making the system advanced, reliable, easy to operate, and highly automated.

10. Large steel rollers with baked paint finish offer good adhesion and corrosion resistance, and have undergone high-precision dynamic balance calibration.

11. The main warping unit moves on the track, while the creel, tensioning frame, yarn storage frame, and bobbin frame are fixed, ensuring that the warp remains centered relative to the creel and bobbin frame, resulting in more uniform yarn tension.

12. The pneumatic safety railing device ensures greater safety and reliability during rewinding.

13. Various types of bobbin frames are available, with spindle spacing and number selectable according to user requirements.

14. Various types of tensioners and warp breakage automatic stop devices are available for optional selection.

15. The warping creel is equipped with a static eliminator, and the rewinding machine is equipped with an oiling device and a pressurizing device.

Main Technical Parameters

Keywords:

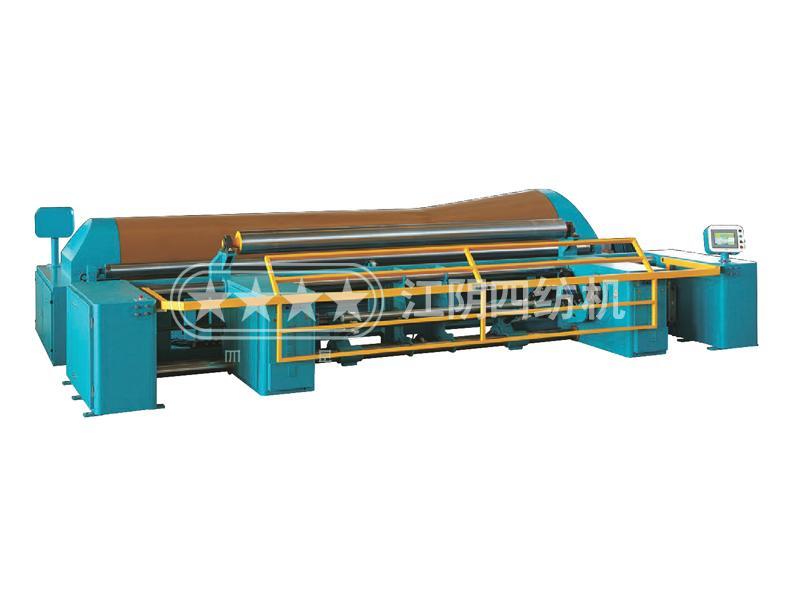

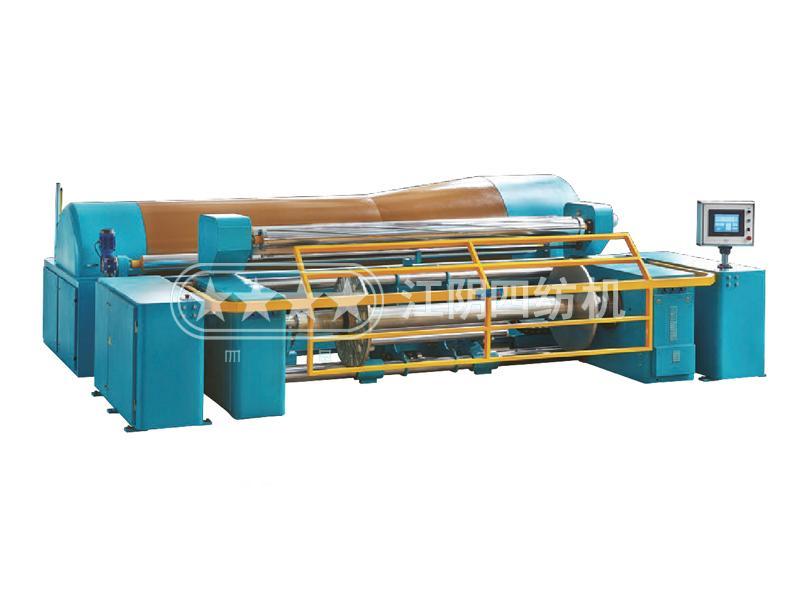

GA163E (Precision) Sectional Warping Machine

Previous Page

More Products

Online Message

We can recommend suitable products for you according to your needs. Please fill in the following form, and we will contact you in time!

Inquire Now

Inquire Now