Fax:86-510-86361211

Add:Changshou, Jiangyin City, Jiangsu Province, China

Postcode:214424

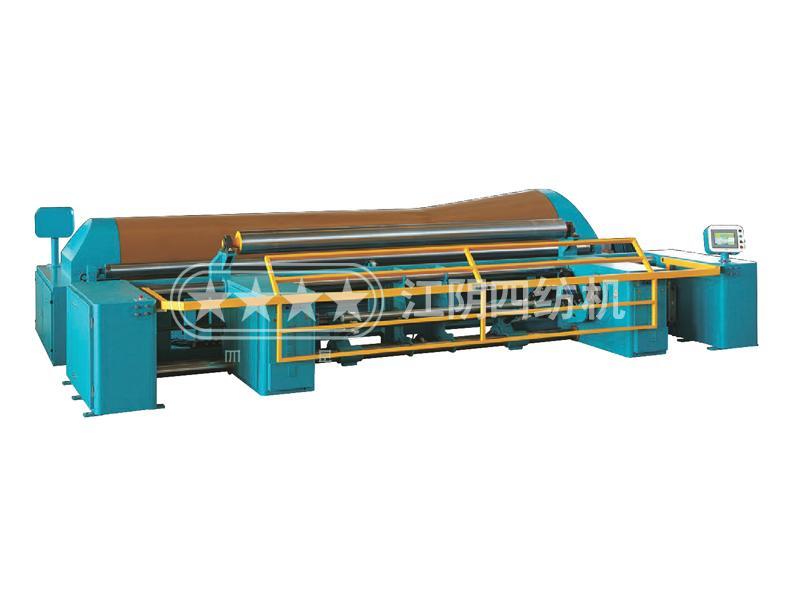

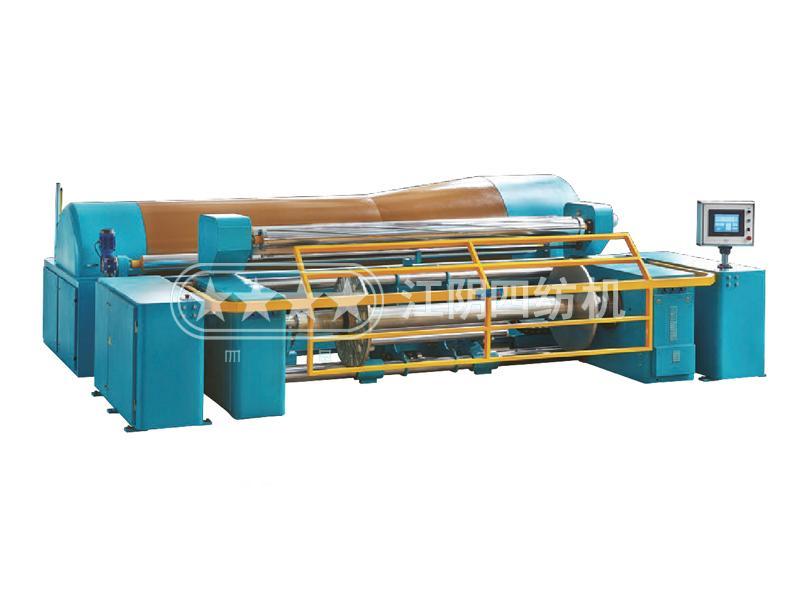

Product Details

Scope of application

To separate the already dyed bundled yarn into single parallel warp yarns and evenly wind them into colored warp beams for sizing and other processes.

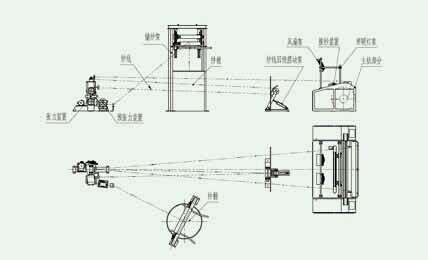

Process flow chart

Main technical features

1. Using a motor and a single-stage pulley to drive the warp beam, with frequency conversion speed regulation, to achieve stepless setting of the linear speed and maintain a constant linear speed during warping.

2. The yarn winding tension can be adjusted and set according to process requirements. A frequency-conversion rotating tension frame is used, and the tension information from the rewinding swing frame provides real-time tension compensation for the yarn. This allows for control of the winding density of the warp beam yarn and ensures consistency of winding density among warp beams. The tension rollers are arranged in a cross pattern for smooth yarn unwinding.

3. A type of yarn storage device can unwind the yarn on the winding warp beam into a yarn bucket, reducing the probability of yarn breakage during reversing and achieving tension control of the unwound yarn during re-warping, improving the quality of the divided warp beam.

4. Various sensors precisely measure the warping length and speed. It has functions such as automatic length measurement, speed measurement, length control, and automatic stop for a certain length of divided yarn.

5. Hydraulic clamping brake for the warp beam, pneumatic braking for the yarn guide roller and tension roller, ensuring smooth and reliable braking.

6. Pneumatic warp beam lifting and lowering, electric warp beam opening and closing, simple and convenient operation.

7. A double yarn separating device and an oscillator on the tension frame allow the yarn to separate smoothly during the process, ensuring smooth yarn separation, increasing warping speed, and the yarn separating device can automatically rise and fall according to the warping speed to prevent yarn entanglement.

8. The machine is equipped with practical devices such as a safety railing safety device, a flying fluff fan frame, and a lighting frame.

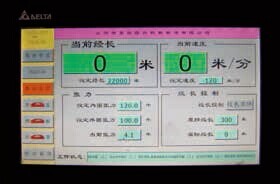

9. The brain touch screen is convenient, intuitive, and displays a large amount of information.

10. The bucket rewinding workbench is optional according to user requirements.

Main technical parameters

1. Warping width: 1600, 1800 (other widths can be customized according to user requirements)

2. Maximum warp beam flange diameter: 800mm, 1000mm

3. Warping speed: ≤ 500m/min

4. Warping motor power: 15KW

5. Yarn separating motor power: 0.12KW

6. Blower motor power: 0.18KW×2

7. Braking distance: ≤ 2M (300m/min)

8. Reed left and right swing range: 0-40mm

9. Maximum tension: 500N

10. Operation display: 10.4 inch touch screen

11. Dimensions: 1600mm 3600mm (length) × 1850mm (width) × 2250mm (height), 1800mm 3800mm (length) × 1850mm (width) × 2250mm (height)

|

Human-machine interface

|

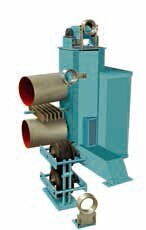

Electrical control system

|

|

Yarn rewinding frame |

Cross-type tension frame with tension rollers |

New type yarn storage frame |

Keywords:

GA261C warping machine

Previous Page

Next Page

Previous Page

Next Page

More Products

Online Message

We can recommend suitable products for you according to your needs. Please fill in the following form, and we will contact you in time!

Inquire Now

Inquire Now