Fax:86-510-86361211

Add:Changshou, Jiangyin City, Jiangsu Province, China

Postcode:214424

Product Details

Scope of Application

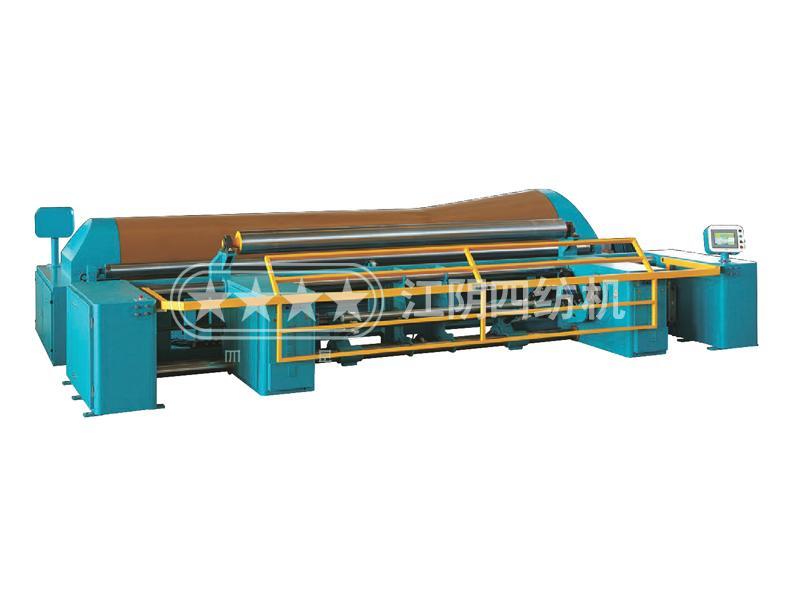

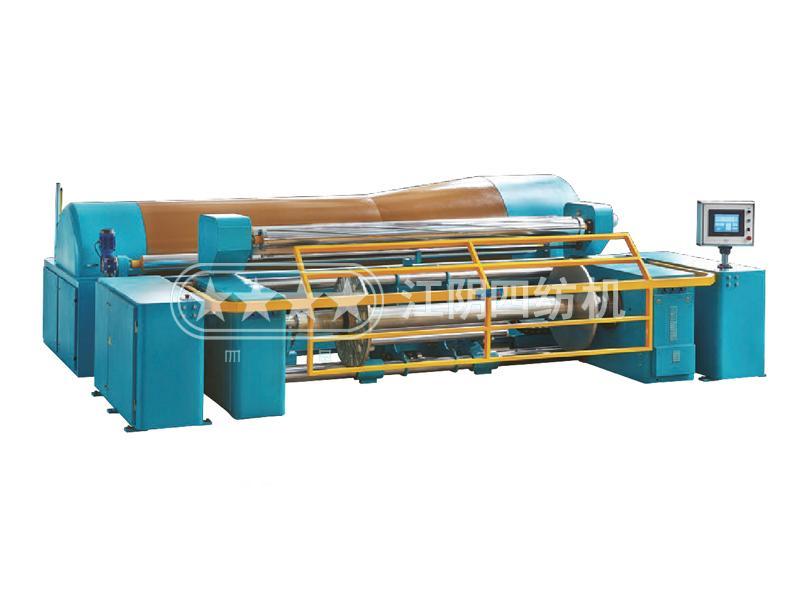

The V-type circulating yarn package frame is mainly used with warping machines for short staple fibers in batches. Its main advantages are its short frame body and the absence of yarn guides between the frame and the expanding reed, making it particularly suitable for certain short fibers sensitive to friction. It achieves high-speed operation at low tension, helping to reduce yarn tension differences and breakage rate during warping; the staggered arrangement of yarn packages optimizes space utilization, and the V-shaped inner side can store spare yarn package frames, facilitating worker operation, shortening the time for changing packages, and reducing downtime during warping. This yarn package frame is particularly suitable for high-speed warping.

Technical Features

1. After inserting spare yarn packages into the yarn frame, they are collectively changed through an electric circulating chain drive rotation, or single-side changing can be selected.

2. The two-wing yarn frames are arranged in a V-shape, using an external yarn guiding method, with no intermediate yarn guides. The yarn unwinds freely, allowing for higher warping speeds.

3. The yarn is gently treated during the warp winding process, minimizing yarn damage.

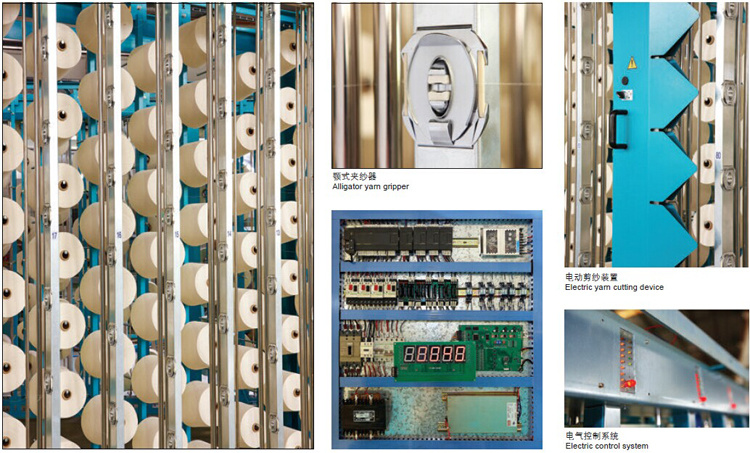

4. The jaw-type yarn clamping device integrates a yarn breakage detection device with self-diagnostic function and a jet device for cleaning the yarn clamper. The open design of the yarn clamper makes threading easier, and when starting and stopping, it applies gentle braking to the yarn, preventing yarn slack during acceleration and deceleration.

5. The yarn breakage detection device integrates a sensor with an automatic detection function for the current number of yarn ends on the yarn frame. It can automatically store the position of the yarn sensor, and even without a yarn sensor, it can still display, improving the efficiency of changing varieties.

6. The sensitivity of the sensor yarn breakage detection can be automatically adjusted according to different yarns, and during yarn breakage, it is displayed on each spindle, each row, and on both sides. The LED display on the front of the yarn frame can also display the specific location of the yarn breakage, facilitating the handling of broken ends and improving production efficiency.

7. The integrated anti-air ring forming device and pre-tensioning rod device provide flexible tension compensation to the yarn during stopping and starting, and the difference in yarn tension before and after can be reduced by adjusting the wrapping angle of the pre-tensioning rod.

8. High-efficiency electric yarn cutting device (optional).

9. An independent control box is provided on the front side of the yarn frame.

Technical Parameters

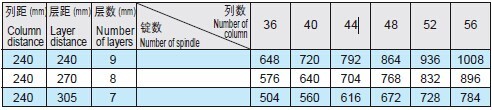

1. The number of spindles is 10x240.

2. Row spacing, layer spacing, number of layers, number of rows, and number of spindles are shown in the attached table

Keywords:

V-shaped loop tube rack

Previous Page

Previous Page

More Products

Online Message

We can recommend suitable products for you according to your needs. Please fill in the following form, and we will contact you in time!

Inquire Now

Inquire Now