Fax:86-510-86361211

Add:Changshou, Jiangyin City, Jiangsu Province, China

Postcode:214424

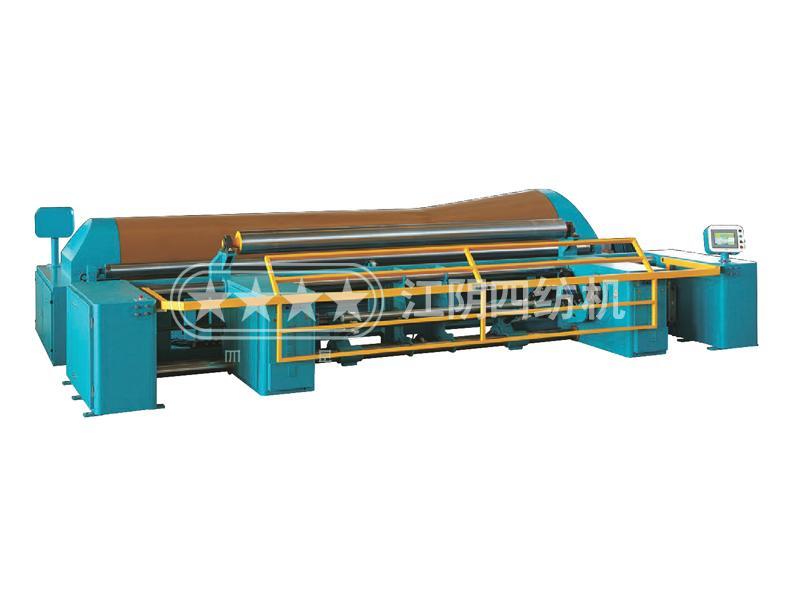

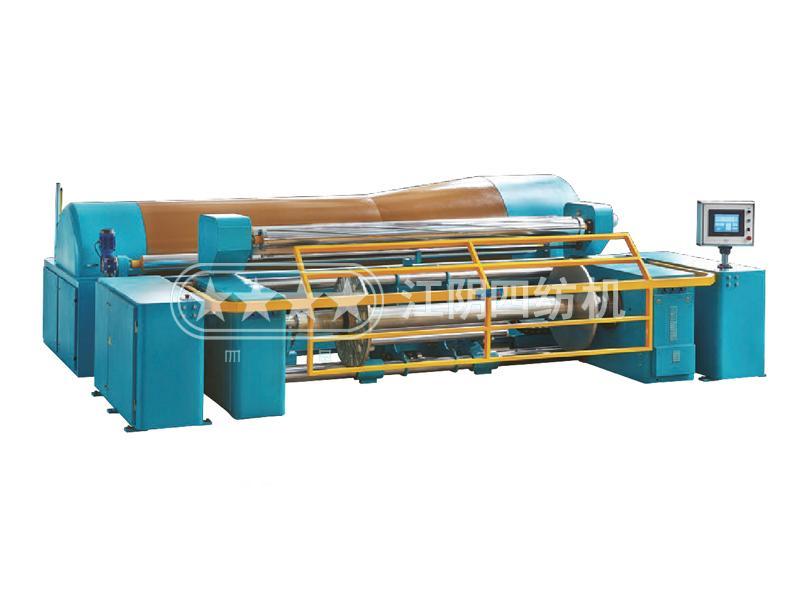

SHGA215C Slitting and Warping Machine / SHGA215C Integral Reverse Roller Machine

Category:

E-mail:

Inquire Now

Inquire Now

Product Details

Application Scope

Sectional warping for fine wool fabrics, strong twisted chemical fiber filament fabrics, dyed fabrics, silk fabrics, towel fabrics, and special industrial fabrics. Can be used as pre-weaving preparation equipment for shuttleless looms such as water jet, air jet, rapier, and projectile looms. Can replace imported sectional warping machines subjected to import.

Main Technical Features

|

⊙ The axial displacement of the warping operating platform is controlled by a high-precision servo motor, and the starting point positioning and section positioning are automatically completed with a single button press. |

Warping Operation Display Screen |

Main Technical Parameters

|

1. Effective Width: 2300(mm) (Basic Type) (Special specifications can be customized according to user requirements) 2. Weaving Beam Flange Diameter: ≤ 800(mm) (Basic Type) 3. Warping Speed: 0 ~ 600(m/min) 4. Creeling Speed: 0 ~ 100(m/min) 5. Warping, Creeling Constant Linear Speed Accuracy: ±2% 6. Braking Distance: ≤ 2(m) (at speed 300m/min) 7. Creel Tension: ≤ 6000(N) (at creel speed ≤ 50m/min) 8. Large Drum Diameter: 1026(mm) 9. Cone Length: 1010(mm) 10. Cone Angle: 90 11. Traverse Speed of Guiding Bar: 0.001 ~ 9.999(mm/r) (Stepless) 12. Guiding Bar Follow-up Accuracy: 0.02% 13. Distance between Reed and Drum: Adjustable |

14. Cone Start Point Positioning: Automatic 15. Section Positioning: Automatic 16. Section Width Setting Range: 0.1 ~ 999.9(mm) (Should not be greater than the length of the yarn guide roller) 17. Creel Spindle Pitch: 300x250(mm) (wool, cotton yarn), 290x290, 220x220 (chemical fiber filament) 18. Number of Creel Spindles: 392 (wool, cotton yarn) 480 (chemical fiber filament) 19. Input Voltage: 3x380V(±10%) 20. Installed Capacity: 30(KVA) 21. Warping Motor Power: 7.5(KW) 22. Creeling Motor Power: 15(KW) 23. Guiding Bar Moving Servo Motor: 1.5(KW) 24. Main Machine Weight: 4500(kg) 25. Creel Weight: 2500(kg) |

|

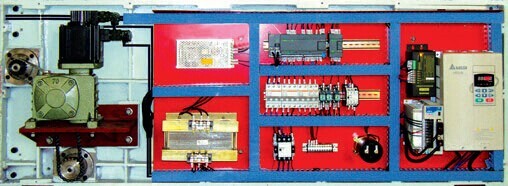

Headstock Control Box, Servo Drive |

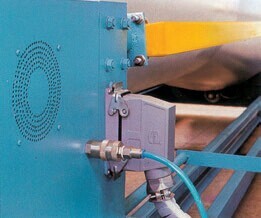

Pneumatic and Electrical Connectors for Mobile Creel and Warping Machine |

Keywords:

SHGA215C Slitting and Warping Machine / SHGA215C Integral Reverse Roller Machine

Previous Page

Next Page

Previous Page

Next Page

More Products

Online Message

We can recommend suitable products for you according to your needs. Please fill in the following form, and we will contact you in time!